Pentaflex Mini Pro

Smoke-permeable polyamide casing for packaging sausages and mini-sausages.

Description

PENTAFLEX-MINI PRO is designed for packaging sausages produced using technologies that include smoking and allow for the production of products with traditional organoleptic characteristics inherent in natural and artificial protein casings.

Advantages of Pentaflex Mini Pro shells:

- The permeability of the casing for smoke makes it possible to roast and smoke the product, which gives the products a pleasant specific taste and aroma of smoking, contributes to the appearance of a coagulated protein crust and a glossy surface of the product under the casing;

- The high mechanical strength of the casing allows forming products not only using manual knitting, but also on various types of equipment, provides high production speed and the possibility of overfilling relative to the nominal caliber. The uniformity of the casing caliber of Pentaflex Mini Pro ensures stable filling on sausage lines and syringe fillers with a twisting device.

- The high heat resistance of the polymers used in the production of the casing significantly expands the temperature range of the casing compared to protein and cellulose casings. The casing is resistant to high temperatures;

- The vapor permeability of the Pentaflex-Mini pro casing is 1.2-1.5 times lower than that of cellulose casings, and is at a level that allows: to achieve the degree of smoking of sausage products with the appearance of the formation of a pronounced taste, aroma and coagulated protein crust on the surface of sausages; to reduce moisture loss during heat treatment and storage of sausages in the Pentaflex-Mini pro casing;

- high oxygen barrier properties compared to protein and cellulose shells provide the following advantages (recommended shelf life of up to 6 days, provided that the finished product is stored at a temperature of 0° to 6°C and a relative humidity of no more than 75%. The manufacturer of the product determines its shelf life based on sanitary conditions of production, technology, and storage conditions);

- preservation of the individual aroma of spices in the finished product throughout the entire shelf life;

- microbiological resistance. The polymers used to produce the casing are inert to bacteria and mold. This improves the hygienic characteristics of both the casing itself and the finished product;

- reduced adhesion to various types of minced meat ensures easy removal of the casing from the finished product without damaging the surface layer of the product, which is especially important for sausages and bratwursts;

The warranty period for the shell before use is 24 months from the date of manufacture.

Region

application

Technical parameters and standards

| Parameter | Pentaflex Mini Pro |

|---|---|

| Calibers (mm.) | 30, 32, 34, 36, 38 |

| Goffering | 30, 32, 34 mm - hard; 34, 36, 38, - soft in mesh |

| Color scheme | 5 colors |

We will help you choose the best solution for your production.

Leave a request — we will consult on the compatibility of materials, diameters, and types of packaging.

Request successfully sent

Thank you for your inquiry, our manager will contact you at the provided email.

Have a nice day

Key

advantages

High barrier properties

Choosing the type of corrugated cardboard

Mechanical strength and elasticity

Heat resistance

Printing and customization options

Wide range of colors and calibers

Extended shelf life of the packaged product

Trust of Global Brands

Sustainable

development

PENTOPAK Company actively implements the principles of sustainable development and strives to reduce its environmental footprint by investing in clean technologies and energy efficiency.

Learn More

Additional Services

Printing on the shell provided by the customer

Design development

After-sales service

Print (on casing and packages)

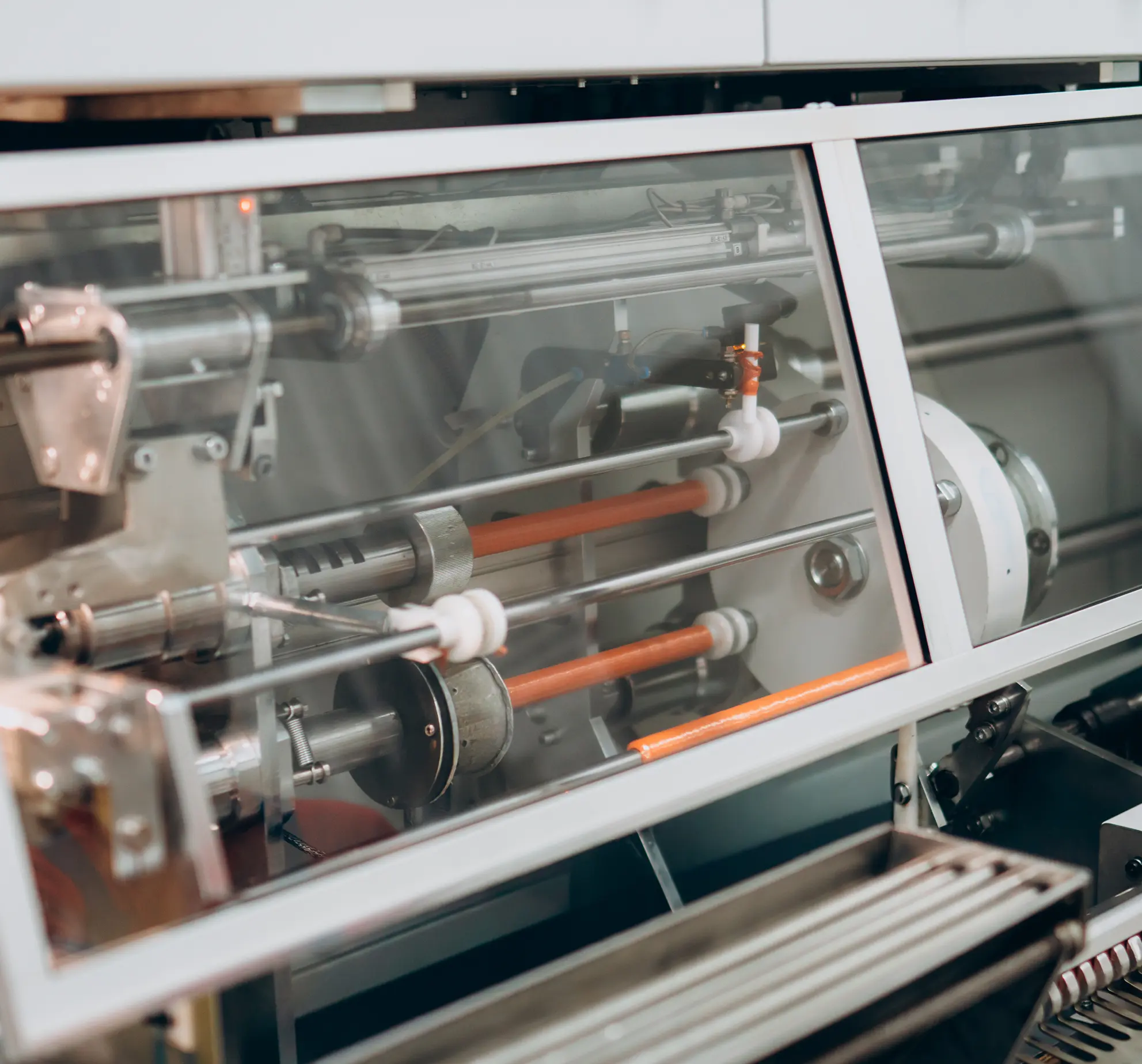

Casing Corrugation

Delivery

Cliché Production

Get a personal offer

Tell us about your request — we will help you choose the best type of packaging, materials, and cooperation format for your business.